Ferromagnetic abrasive Particle Analyzer

Analysis of metallic abrasive particles in lubricants plays a key role in monitoring lubrication processes. Conventional methods are not optimized for the analysis of abrasive particles. For example, the Rotating Disc Electrode Optical Emission Spectrometer (RDE-OES) is able to determine small size metal particles in lubricants precisely. However, this method is limited by low carrying capacity and low activation energy. Consequently it is not suitable analyzing larger particles (larger than 10 µm). Although the Direct Reading Ferrograph (DRF) is good on detecting large ferromagnetic particles, it indicates a correlation coefficient instead a concentration directly, which makes the data analysis and the conclusion difficult. Additionally, the handling of DRF is complicated, the time-consuming large, and toxic chemicals are required.

In order to meet customer requirements and to realize a quick, precise and user-friendly analyze of ferromagnetic abrasive particles in lubricants, we have developed successfully the MT100-Series, the fully automatic ferromagnetic abrasive particle analyzer of the newest generation. The MT100 series are both sensitive and reproducible because of its electromagnetic measuring principle. The concentration of ferromagnetic abrasive particles in various oil media can be determined within seconds. The measured concentration can be displayed directly (in µg / L or ppm). It makes the analysis and processing of measurement results much easier.

Measuring principle

A highly sensitive electromagnetic coil is integrated in the device. During the measuring process, ferromagnetic particles in the sample cause a variation in the magnetic signal. In this case, the concentration of ferromagnetic abrasive particles in the sample is perfectly correlated with the intensity of the electromagnetic induction.

Features

- Sensibility: The limit of detection for ferromagnetic abrasive particles in the oil media is 1 ppm.

- Test time: From sample feeding to result displaying takes only seconds, which realize a quick analysis of large sample quantities.

- Usability: The operation of the MT100 series is extremely simple. Professional knowledge and lengthy training are not required.

- Mobility: The MT100 series are compact, stable and shock-resistant, and therefore applicable for on-site operations.

- Compatibility: The MT100 series are able to measure all kinds of hydraulic, gear, mineral and synthetic oils as well as lubricating greases.

- Occupational safety and Eco-friendliness: The analysis with the MT100 series requires neither sample preparation nor evacuation of the device using toxic chemicals. Thus, the operation is absolutely safe for both staff and environment.

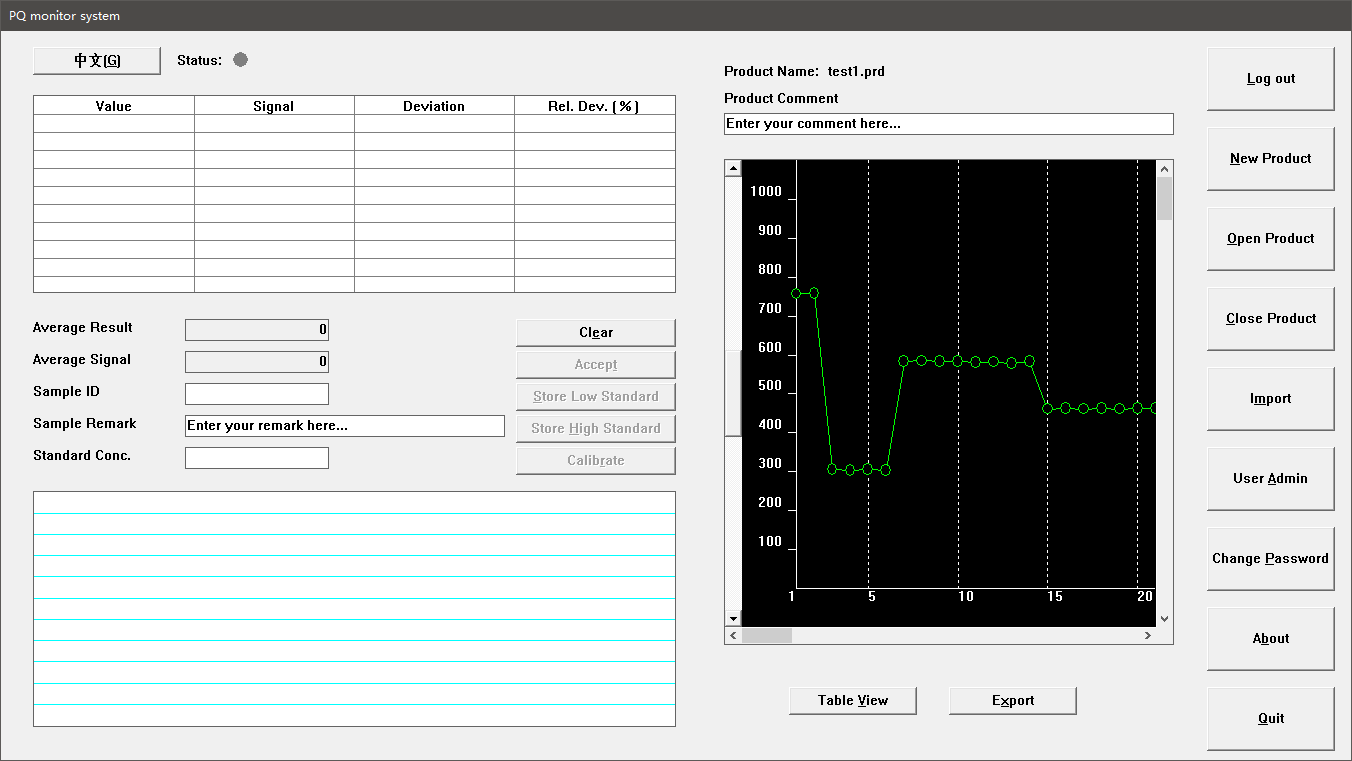

- Operating software: Windows system with data storage, indexing and correction as well as trend analysis function.

Parameters

Limit of detection: 1 mg/L

Detection range: 0-2000 mg/L

Smallest measurable abrasive particle: 1 µm

Sample volume: 2 ml

Working temperature: 10-55 oC

Power supply: 220V DC or internal battery

Dimensions: 90×240×150 mm

Total weight: 1.8 kg

Modelle

MT100B: Basic model, only driven by external PC or laptop, without battery.

MT100ET: Portable, with touchscreen and rechargeable Li battery for 8 hours mobile operation.

MT100E: Portable, driven by laptop, with rechargeable Li battery for 8 hours mobile operation.